Intelligent Piling System

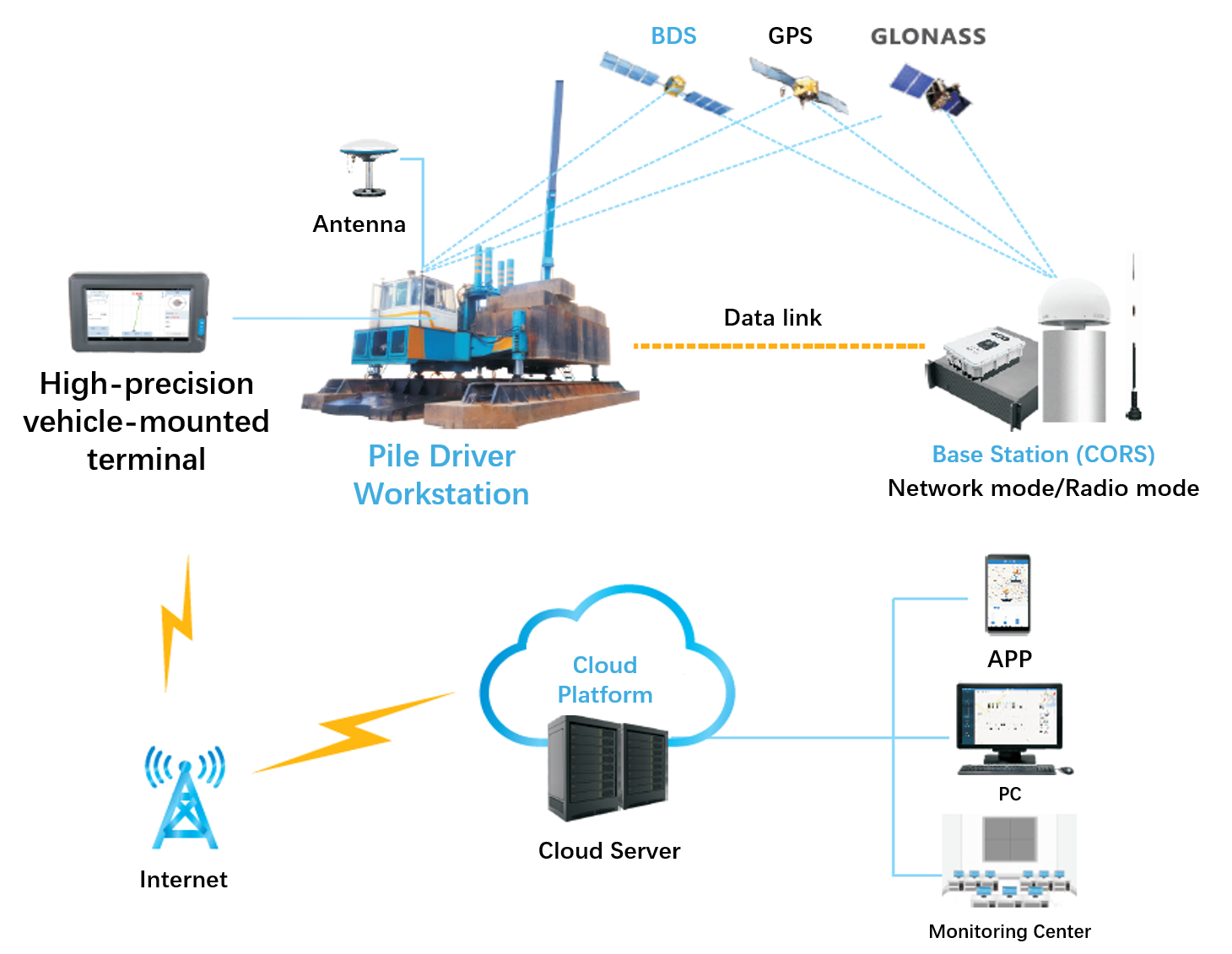

The SOUTH Intelligent Piling System is an intelligent system that integrates a number of cutting-edge technologies such as high-precision satellite positioning technology, Internet of Things technology, mobile internet technology, multi-functional sensor technology, and cloud computing technology. The system uses the high-precision integrated dual-antenna mode of the receiving station of SOUTH to receive the differential correction data of the base station to determine and solve the front and rear antenna coordinates and attitude, and to achieve piling and stakeout with professional piling software to improve the efficiency of piling operations.

1. No need to laying line:

In the traditional mode, two people need to cooperate with each other to stake out and check piles, which consumes time. Using this system can quickly find the required pile position under the command of the mobile terminal, greatly improving the construction efficiency.

2. Reduce errors:

From the traditional pullout period, theodolite era, and the total station era, the South has always aimed to improve the accuracy during the construction process. Using this system can directly reduce the error rate during artificial stakeout and review, improving precision of pile formation.

3. All-weather operation:

The ground on the construction site is messy and muddy during the rainy season. It is difficult to find points at night, rain, and foggy weather, and it is impossible to operate. This system is not restricted by the site and can be operated normally at night and on rainy days.

4.Intelligent cloud platform:

Based on cloud computing technology, through the integrated mode of the Internet of Things and the Internet, real-time monitoring and management of personnel, equipment, and tasks allows construction managers to quickly and accurately control the construction quality, construction progress, to receive early-warning information of the project site, and to complete remote project management, reducing management costs.

Case No.1

Case time: October 2018

Client: One Engineering company in Guangdong Province

Project background: The company has a large number of widespread project sites. Before using smart piling equipment, the traditional mode of RTK or total station was still used for stakeout. Each site requires at least two surveyors. The number of staff and the construction period was large and the progress was slow.

Iconic event: Completed the installation of 4 sets of piling systems, greatly reducing the labor of surveyors, technical staffs began to involve in more project management works, and the progress of the construction period was guaranteed.

Project Achievements / Values: Solved the shortage of payrollers, optimized human resources, and improved work efficiency.

Customer evaluation: The equipment is very powerful and helped me solve the shortage of surveyors. Now I make more money and it is faster.

Case No.2

Case time: November 2018

Client Unit: One Engineering company in Jiangsu Province

Project background: Before using smart piling equipment, the company still used the traditional operation mode of theodolite payoff. When the site was muddy or the site was poor during the rainy season, stakeout was difficult, the accuracy and the efficiency was slow.

Iconic event: The installation of 9 sets of piling systems was completed, which solved the problems of difficult stakeout, low efficiency, and low accuracy, and greatly improved work efficiency.

Project Achievement / Value: Under the traditional operation mode, about 25 piles can be piled per day per pile machine. After installing the equipment, each pile can pile about 40 piles per day, and the work efficiency is increased by 60%.

Customer evaluation: Beidou equipment is now used, which is not affected by the weather site. The problems have been solved and the stakeout and piling efficiency is very high.