Pavement Engineering Management System

This system installs various sensors at key nodes of construction work, adopts high-precision positioning, GIS, Internet of Things data collection and other advanced technologies to collect construction data, and uploads the data to the NDCS digital construction cloud platform in real time. Combined with data analysis technology, it can comprehensively, realistically and dynamically reflect the various loops in the construction process, playing an important role in guiding, managing and warning for construction operations.

1. Paving Management System:

Temperature monitoring: Through infrared temperature sensor, collect the temperature data of the entire paving surface, real-time monitor the temperature separation of asphalt pavement.

Construction positioning: Use the differential calculation between the base station and the mobile station to perform centimeter-level positioning of the paver.

Paving speed: real-time collect and monitor the paving speed and paving trajectory.

Remote monitoring: The data is transmitted to the NDCS platform and the onboard control terminal in real time, and displayed synchronously on the on-site display terminal.

2. Compacting Quality Managemen system:

Real-time display of rolling track and rolling pass rate to effectively prevent overpressure and underpressure

Real-time display of the compaction status of the entire working surface, including index information such as roller compaction and compaction degree, and guide the operator in construction to improve construction quality

Real-time positioning and compaction of weak areas to improve detection efficiency

Real-time return of the entire process of compaction data to the NDCS platform

Cases:

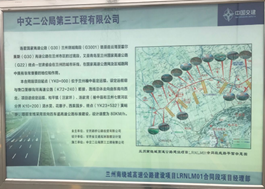

1. Shenzhen Outer Ring Expressway Project

2. Lianhuo National Highway Project